Aiming to increase recycling rates

Through research and product development, we are advancing our goals to improve recycling efficiency and increase recycling rates. Recycling can be made more efficient by

- collection is brought as close as possible to the people who produce the waste, so collection containers must be space-efficient and fit in with their surroundings

- emptying is done in a cost-effective way

- the collection point is safe for both the emptier and children and adults in the yard

- a collection solution that is responsible and reduces greenhouse gas emissions

A large Molok team and partners as a resource

A large Molok team is needed to identify development needs and provide insightful implementation solutions. This includes skilled product development designers, knowledgeable sales and resellers, customer service, production, quality managers, product support and procurement professionals.

In addition, we work closely with an extensive network of experts. This includes key suppliers, universities, specialised experts, design agencies and financiers such as Business Finland.

The international IFAT fair is an important meeting point for our extensive network to showcase Molok innovations and plan for the future.

We promote responsible waste collection practices

EcoFrame framing is the latest product committed to sustainable development. The transition from traditional composite framing to EcoFrame is a significant step towards reducing environmental impact. Unlike composite panels, EcoFrame can be recycled at the end of its life cycle.

From carbon footprint to carbon handprint

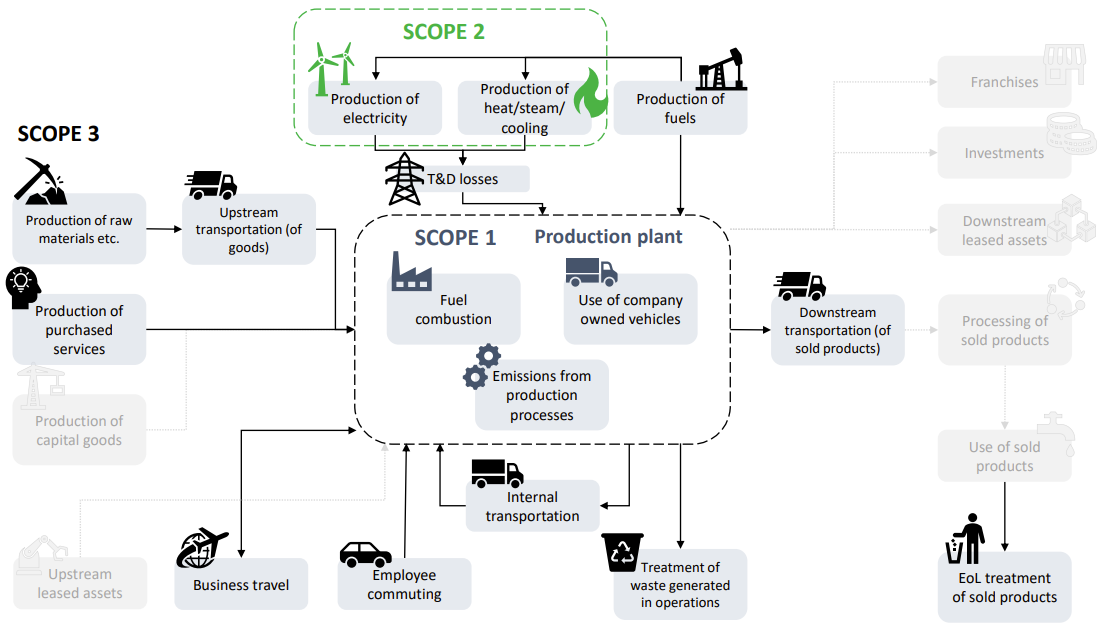

To reduce our carbon footprint, we need to identify the main development needs to reduce the negative impacts of our activities. We also need to monitor the development of the positive impacts of our activities. Therefore, we have commissioned carbon footprint calculations for both our organisation (scope pictured below) and our products MolokClassic and MolokDomino according to the GHG protocol / ISO 14067.

For MolokDomino, we have also commissioned a calculation of the carbon handprint. This compared deep collection with conventional surface collection bins.

The experimental setting was the actual situation at the surface collection bins in five housing associations in the capital region. In the calculation, surface collection was replaced by MolokDomino/MolokClassic deep collection. The collection bins were emptied using trucks running on 100% renewable fuels. The fractions collected were mixed waste, biowaste, cardboard, plastic, glass, metal and paper.

The final result of the experiment was that the CO2 emissions during emptying were about 50% higher for surface bins than for MolokDomino/MolokClassic deep containers. Emissions were reduced by halving the transport traffic due to the reduced frequency of emptying.

We are exploring opportunities to increase the use of recycled materials in our products

Emissions reductions will also be achieved by using more and more recycled materials in the manufacture of deep collection containers.

One of the areas to be explored is adding recycled material to our HDPE plastic components. Our aim in the first phase is to reach 35% recycled content in our production mix. By adding recycled material to virgin material, we are aiming for the same level of durability as virgin material throughout the long life of our products.

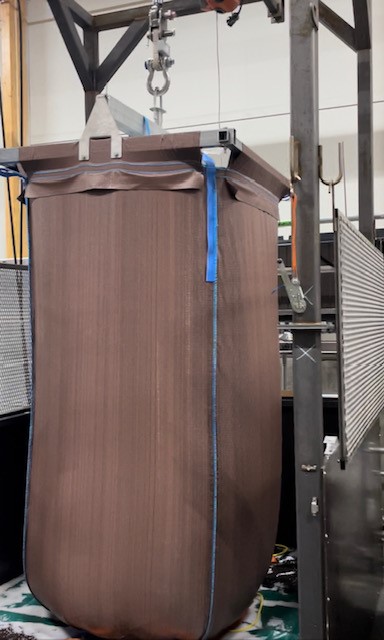

Extensive testing and measurement is needed to ensure the performance of materials. Test pieces have been cast both in the University of Tampere's test laboratory and in production at Molok Oy's factory.

Another area to be explored is the reduction of CO2 emissions from our concrete pits. The most challenging ingredient in terms of CO2 emissions from concrete wells is cement, which requires high temperatures to produce. We aim to halve the CO2 emissions from our concrete wells.

We have done extensive research into the technologies available, their availability, effectiveness, risks and viability. While some very low-carbon implementations emerged from various sources, however the durability of these castings was nowhere near the demanding endurance rating of the thin-walled Molok type of a well.

The use of recycled or low-carbon materials is constantly increasing

Based on above mentioned tests we have started to sell MolokDomino Low Carbon model. This model has 52% lower CO2-emissions compared to the reference well of 2019.

In year 2024 our project to increase the recycled materials in our HDPE plastic wells has progressed well and we have started production in Q2 2025.

We do not compromise on safety

At Molok Oy, safety is a priority value that we do not compromise on.

Our products are built to strict European standards:

-EN 13071-1:2019

-EN 13071-2:2019

-EN 13071-3:2019

-EN ISO 21898

Among other things, we test sacks and their structures with high tensile weights. We also carry out endurance tests on rigid lifting containers in cold laboratory conditions.